Innovative solutions and research facilities for the needs of modern automotive industry

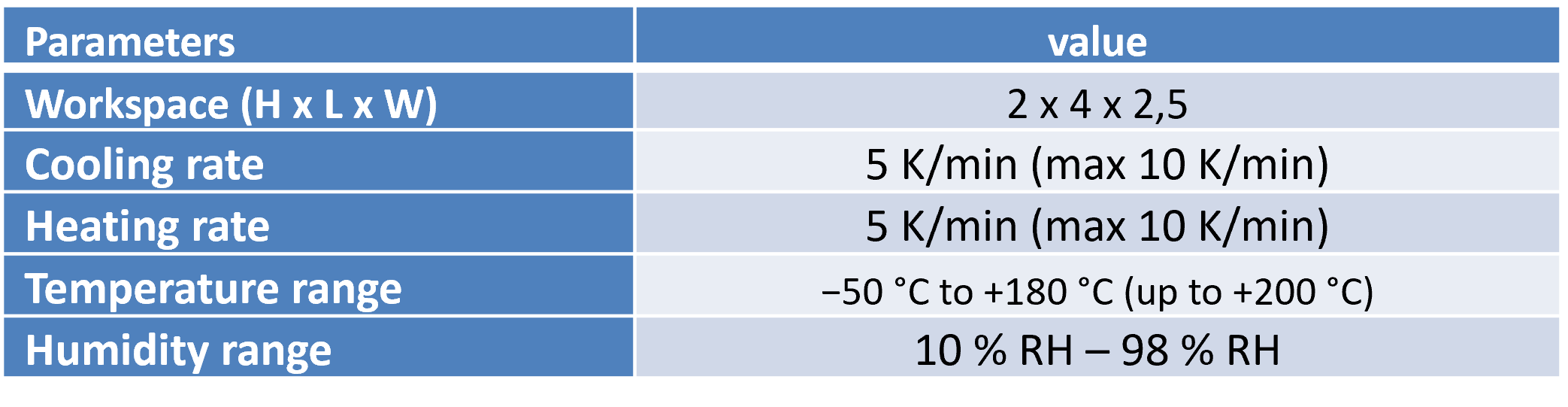

Walk-in climatic chamber for cyclic corrosion and aggressive climate testing (salt mist, condensation, temperature and humidity cycling)

The walk-in climatic chamber is designed for cyclic corrosion and aggressive climate testing in accordance with:

- VDA 233-102:2013-06,

- PV 1210:2016-02,

- PV 1209:2023,

- PN-EN IEC 60068-2-52:2018-05 (Test Kb),

- DIN 55635:2019-05 and EN ISO 11997-3:2023-10.

It enables controlled simulation of salt mist exposure, humidity condensation, temperature variation and drying cycles for the evaluation of corrosion resistance of coatings, components, and assemblies.

Large Dust and Sand Test Chambers for Ingress Protection and Surface Erosion Testing

The Large Dust and Sand Test Chambers are designed for evaluating the resistance of components and enclosures to dust ingress and abrasive particle exposure under controlled conditions.

- The vertical dust chamber operates according to ISO 20653, IEC 60529, and EN 60068-2-68 standards, providing uniform dust flow for testing large components such as battery pack housings, e-drive units, and electronic enclosures.

It features internal dimensions of approximately 2.5 × 2.0 × 2.5 m (H × D × W) and a maximum load capacity of 700 kg. - The horizontal dust and sand chamber complies with MIL-STD-810 H and EN 60068-2-68, enabling simulation of wind-blown dust or sand exposure and the sandblasting effect on component surfaces.

Different media such as Arizona dust, talc, and cement powder can be used, with adjustable dust concentration and airflow velocity to replicate real environmental stress conditions.

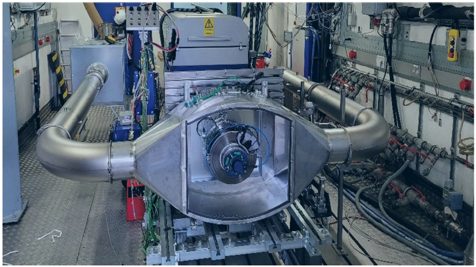

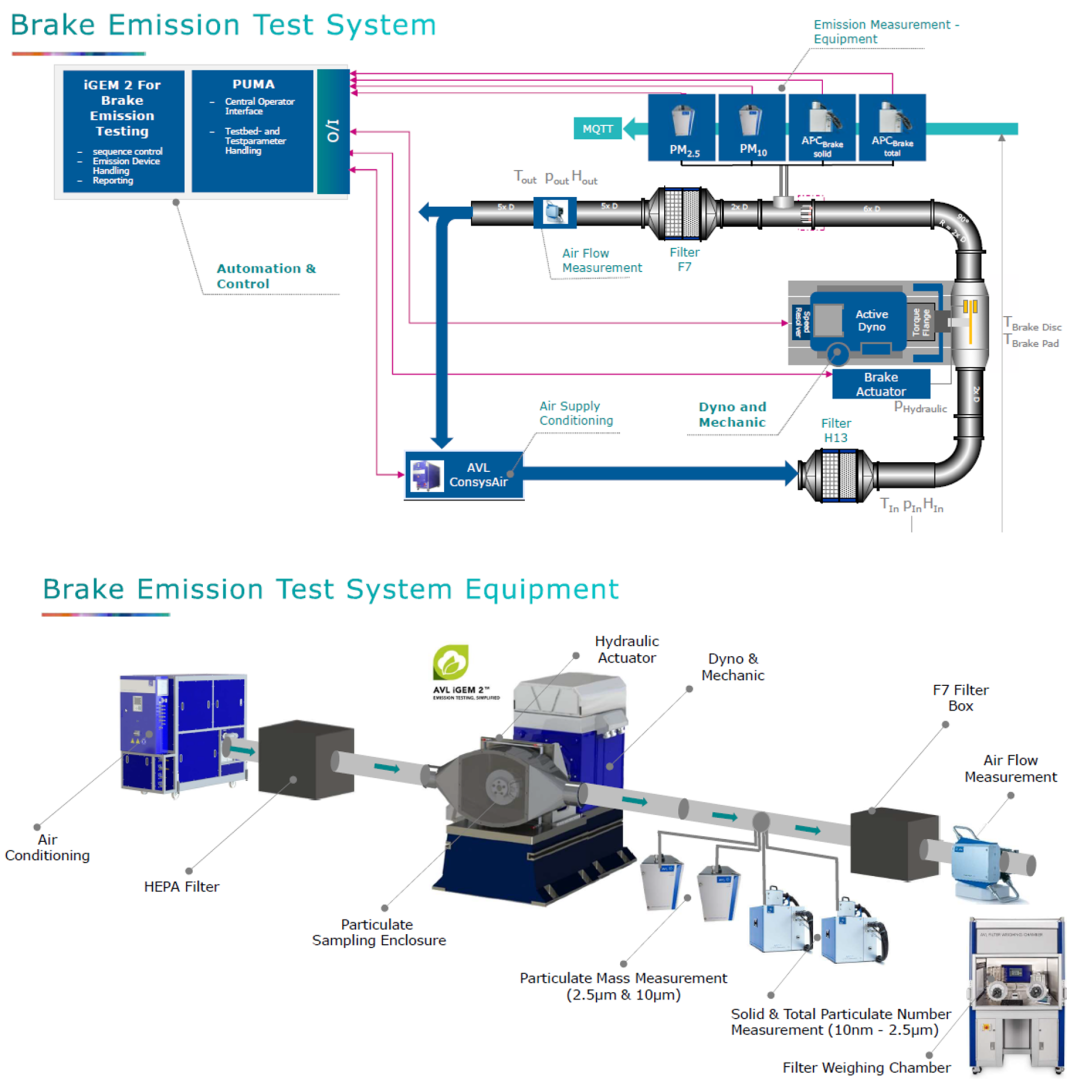

Brake Emission Test Stand according to UN GTR No. 24 (EURO 7 compliant)

- The Brake Emission Test Stand enables testing in accordance with the United Nations Global Technical Regulation No. 24 (UN GTR 24) methodology, ensuring full compliance with the upcoming EURO 7 emission requirements.

- The system allows precise measurement of brake wear, particulate matter (PM) emissions, and particle number (PN) emissions generated during braking events.

- It supports testing of Light-Duty Vehicles category 1-1 (M1) and 2 (N1) with a fully laden mass below 3500 kg, under controlled thermal and dynamic conditions representative of real-world operation.

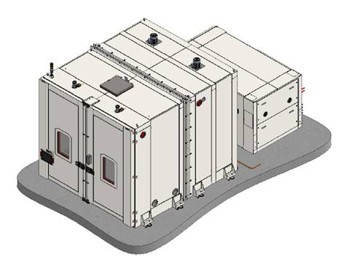

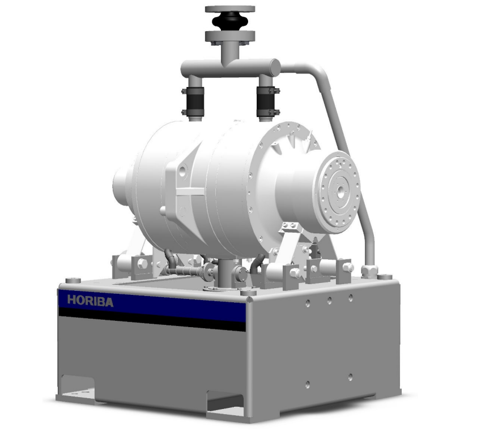

High-Power Engine Test Bench (2.1 MW) for Heavy-Duty and Non-Road Applications

- The new high-power engine test bench has been designed exclusively for testing large engines used in:

- heavy-duty,

- military,

- rail,

- NRMM,

- and marine applications.

- Equipped with a HORIBA hydraulic dynamometer capable of absorbing up to 2.1 MW of power and torque up to 15 000 Nm, the facility allows comprehensive development, durability, and certification testing under fully controlled operating conditions.

- A dedicated cooling circuit enables continuous operation of high-output powertrains, while flexible fuel infrastructure supports multiple fuel types, including:

- diesel,

- gasoline,

- military and jet fuels,

- as well as gaseous fuels such as CNG and LPG.

- The test bench is fully instrumented for advanced performance, emissions, and endurance evaluation.

Innovative solutions and research facilities for the needs of modern automotive industry

The BOSMAL Institute has obtained funding for a project entitled “Expansion of the Competence Center – development of modern drive systems.” The following will be purchased as part of the project:

- Walk-in climate chamber

- Dynamometer cabin for testing high-power engines

- Dynamometer

- Chambers for dust resistance testing

- Irradiation system for sunlight resistance testing (for large objects)

The target group will primarily include vehicle manufacturers, suppliers of automotive parts and components, as well as research institutes and scientific centers involved in innovation in the automotive industry. The BOSMAL Institute also directs its offer to companies involved in electromobility, autonomous vehicle systems, as well as manufacturers of environmentally friendly materials and technologies used in transport, etc. These services will be dedicated to customers looking for advanced tools for testing and implementing modern technological solutions, supporting them in increasing the efficiency, safety, and sustainable development of automotive products.

The main objective of the project is to expand the existing research infrastructure at the BOSMAL Institute.

Project value: PLN 22,388,620

Co-financing: PLN 8,955,448

Back

to top