- Dynamic Hydraulic Test Bench for Mechanical Shock and Inertial Load Testing

- Advanced “Euro 7 Ready” Emission Measurement Benches for Engine Dynamometer Testing

- Particulate matter counter PN10 / PN23

- MEXA Cube PEMS System

- EMC testing in ALSE chamber

- EMC testing – System for Testing Immunity to RF

- HV EMC Test System for High-Voltage Component Testing

- Expansion of the Competence Centre

Expansion of the Competence Centre – development of modern drive systems

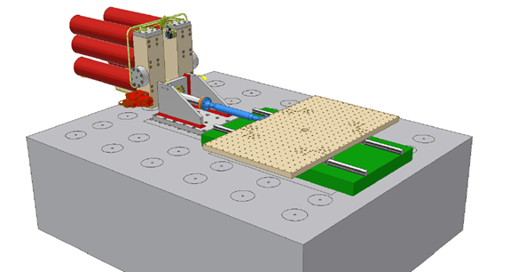

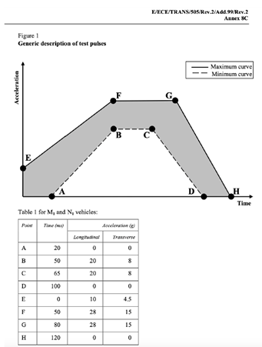

Dynamic Hydraulic Test Bench for Mechanical Shock and Inertial Load Testing (UNECE R100 / ISO 6469-1)

The dynamic hydraulic test bench is designed for the performance of 9C “Mechanical Shock” tests in accordance with UNECE Regulation No. 100, and “Inertial Load at Vehicle Crash” tests according to ISO 6469-1:2019, section 6.4.1.1.2. The system allows testing of components and assemblies with a total mass of up to 600 kg (including instrumentation), enabling validation of structural integrity and electrical safety of high-voltage systems during simulated crash-like mechanical shocks.

Main technical parameters

- Hydraulic actuator: 400 kN force, 800 mm stroke, maximum speed 9 m/s

- Hydraulic accumulators and actuator bracket for energy storage and dynamic impulse generation

- Test table: linear-bearing platform with a surface area of 245 × 145 cm

- Hydraulic power unit (air-cooled): working pressure ≥ 280 bar, tank capacity ≥ 200 L, nominal flow ≥ 40 L/min

- Hydraulic manifold: rated working pressure ≥ 280 bar

- Controller: closed-loop feedback control with dedicated test software enabling the generation and iteration of test signals in compliance with the acceleration pulse profile defined in UNECE R100 and ISO 6469-1

This advanced setup allows precise reproduction of high-energy mechanical shocks and acceleration pulses to assess the durability and crash safety of battery systems and other components used in vehicles.

This advanced setup allows precise reproduction of high-energy mechanical shocks and acceleration pulses to assess the durability and crash safety of battery systems and other components used in vehicles

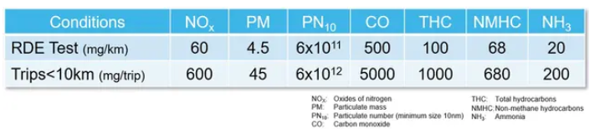

Advanced “Euro 7 Ready” Emission Measurement Benches for Engine Dynamometer Testing – AVL AMA i60 SII and AVA SESAM i60 FT

- The AVL AMA i60 SII and AVL SESAM i60 FT emission benches represent state-of-the-art systems for exhaust gas analysis in accordance with the latest and upcoming emission legislation, including Euro 7, Euro VI, Stage V, and EPA 1065/1066.

- Designed for continuous measurement of raw exhaust gases from diesel, gasoline, CNG, LPG, and alcohol-fuelled engines, they provide outstanding accuracy and long-term stability.

- Both systems employ ISO 17034 certified calibration gases (Certified Reference Materials), ensuring traceability, accreditation compliance, and high data reliability.

- The AMA i60 SII enables precise determination of THC, CH₄, NO/NO₂/NOₓ, CO₂, CO, and O₂, while the SESAM i60 FT allows simultaneous quantification of more than 20 gas components, including N₂O and NH₃ for current standards, as well as formaldehyde and other species foreseen for future Euro 7 regulations.

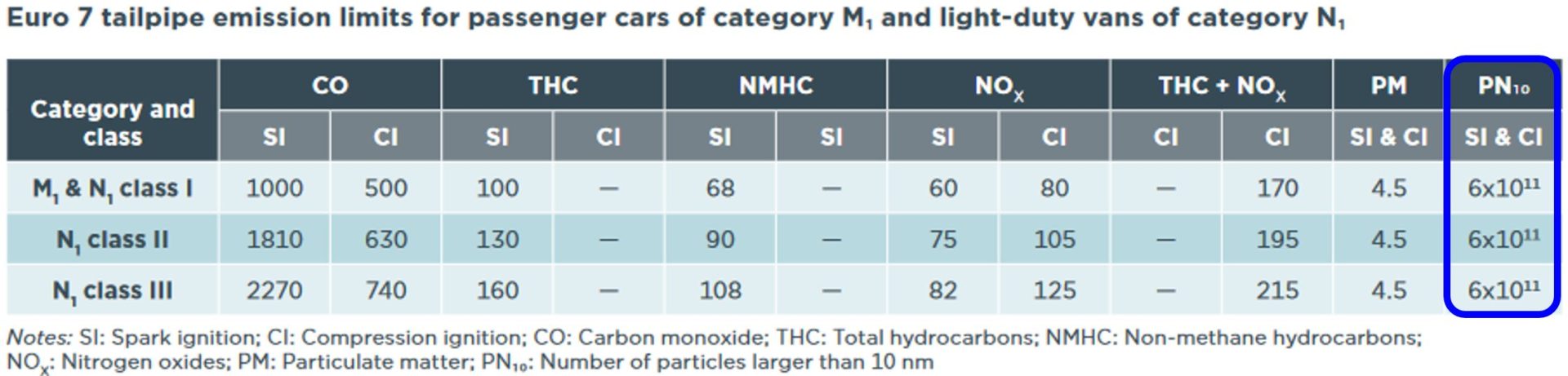

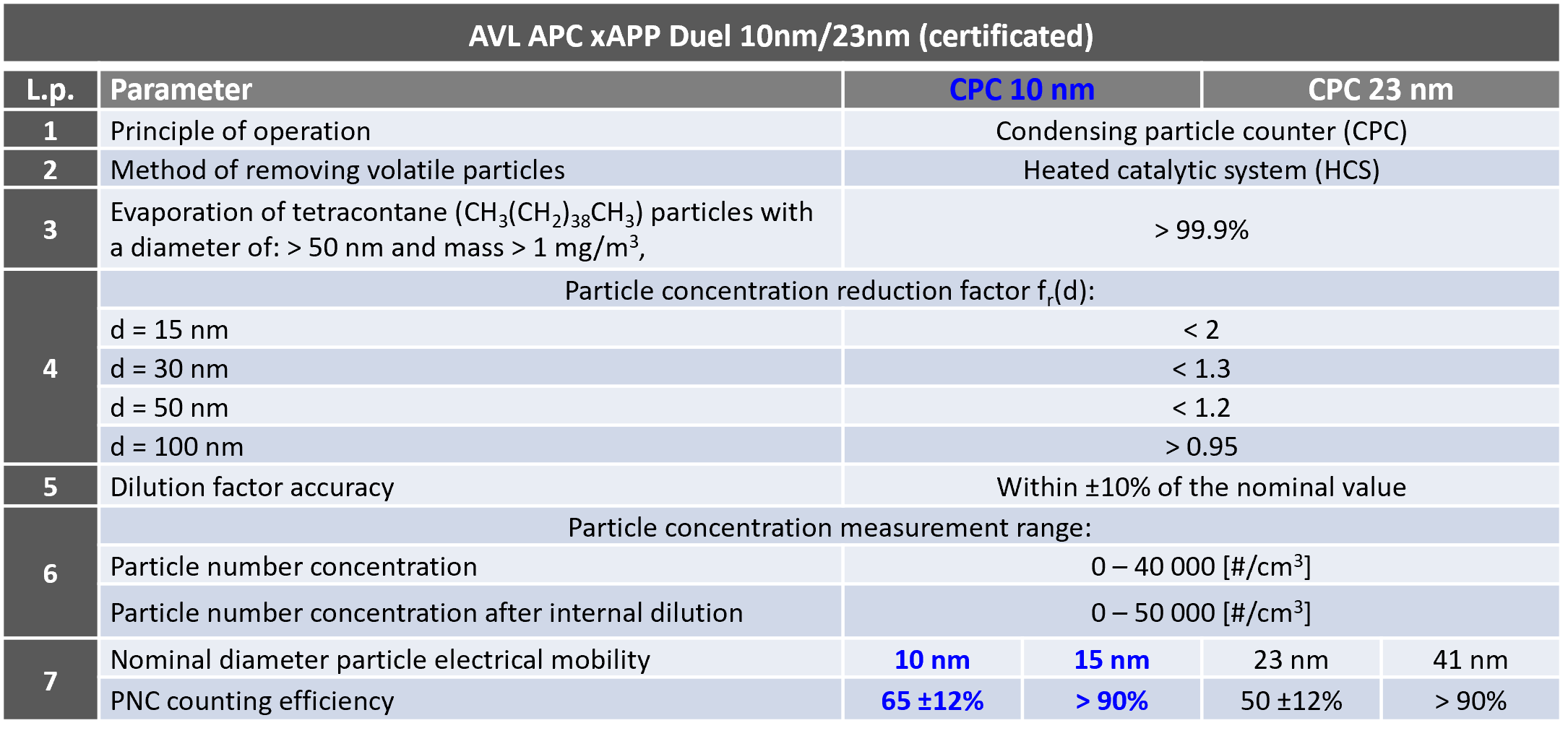

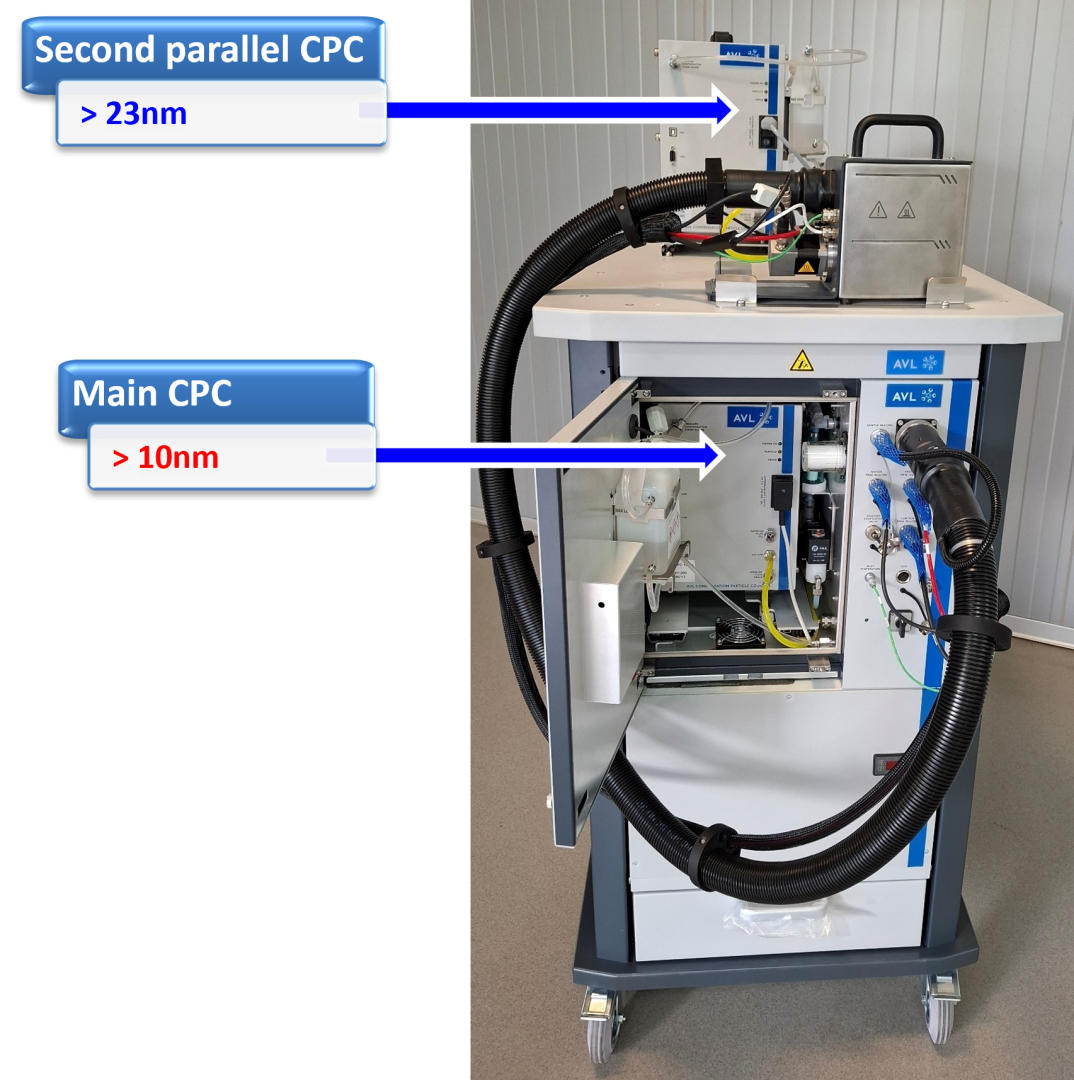

Particulate matter counter PN10 / PN23 – AVL APC xAPP 10/23 nm

The AVL Particle Counter is a measurement device for counting engine’s exhaust particle number

emissions. The APC xApp 10/23™ fulfill the specifications according to the draft requirements GTR15 10nm for sub-23nm emission measurements as proposed by the UNECE PMP Group. Parallel measurement of 10nm and 23nm provide valuable data for actual and future PN specifications.

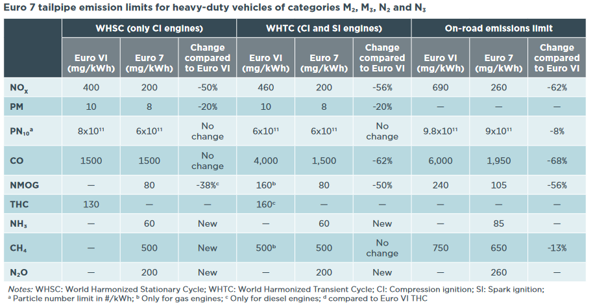

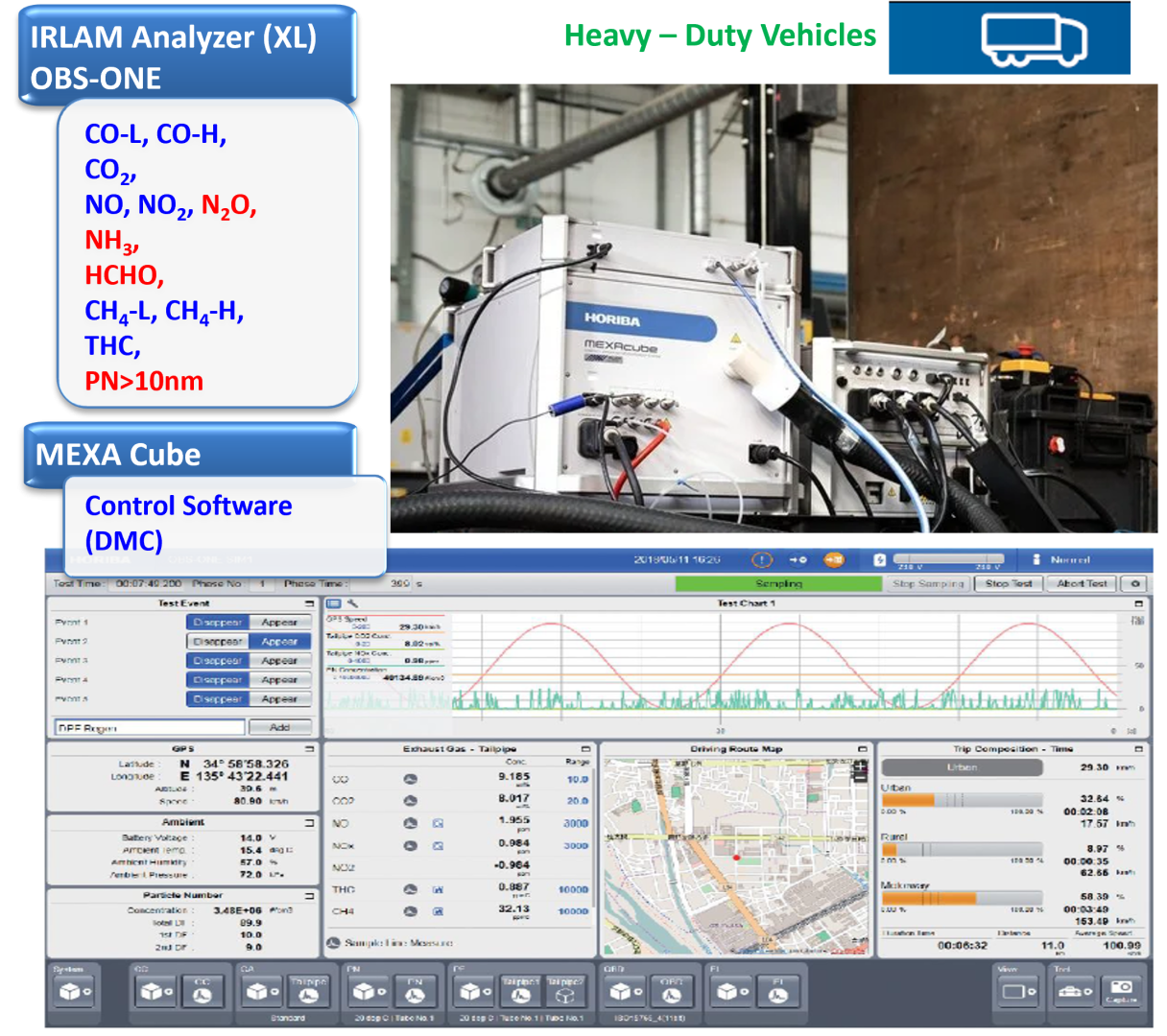

MEXA Cube PEMS System – RDE emission testing

MEXAcube measures a comprehensive range of emission concentrations. HORIBA’s new MEXAcube is suitable for both real-world and laboratory measurements. Designed to meet various testing needs, MEXAcube is suitable for Euro 7 / GB 7 regulatory components testing, Real Driving Emissions (RDE) testing, and alternative fuel / H2 engine analysis.

The OBS-ONE PN unit is an on-board emissions measurement system for analyzing the solid particle number concentration within the specified particle size range under real-world driving conditions.

MEXAcube (IRLAM Analyzer (XL)) measures a comprehensive range of emission concentrations, including CO, CO2, NO, NOx, NO2, N2O, NH3, HCHO, CH4, by using QCL-IR (quantum cascade laser infrared spectroscopy) and THC by using FID (flame ionization detection) principles. It also monitors air-to-fuel ratio, exhaust flow rate, GPS data, and environmental conditions while calculating mass emissions. The accompanying Data Post Processing (PP) software performs basic calculations such as mass emissions and fuel consumption. Additionally, it enables regulation-based analysis and reporting, enhancing the analyzer’s utility in various applications.

EMC testing in ALSE chamber (Absorber-Lined Shielded Enclosure)

- The ALSE chamber enables full-compliance electromagnetic compatibility testing in accordance with CISPR 25, ISO 11452, and MIL-STD-461G standards.

- The facility allows component testing with masses up to 700 kg and offers usable internal dimensions of 7.55 m × 6.05 m × 3.10 m (D × W × H).

- The working frequency range extends from 10 kHz to 40 GHz, covering conducted and radiated emission as well as immunity testing for automotive, military, and industrial applications.

- The test setup provides a programmable DUT power supply up to 1500 VDC / 2 × 500 A, as well as connections for cooling circuits, compressed air, and communication interfaces.

- The chamber is equipped with video monitoring and dedicated control software enabling continuous visual supervision and functional verification of the Device Under Test during exposure.

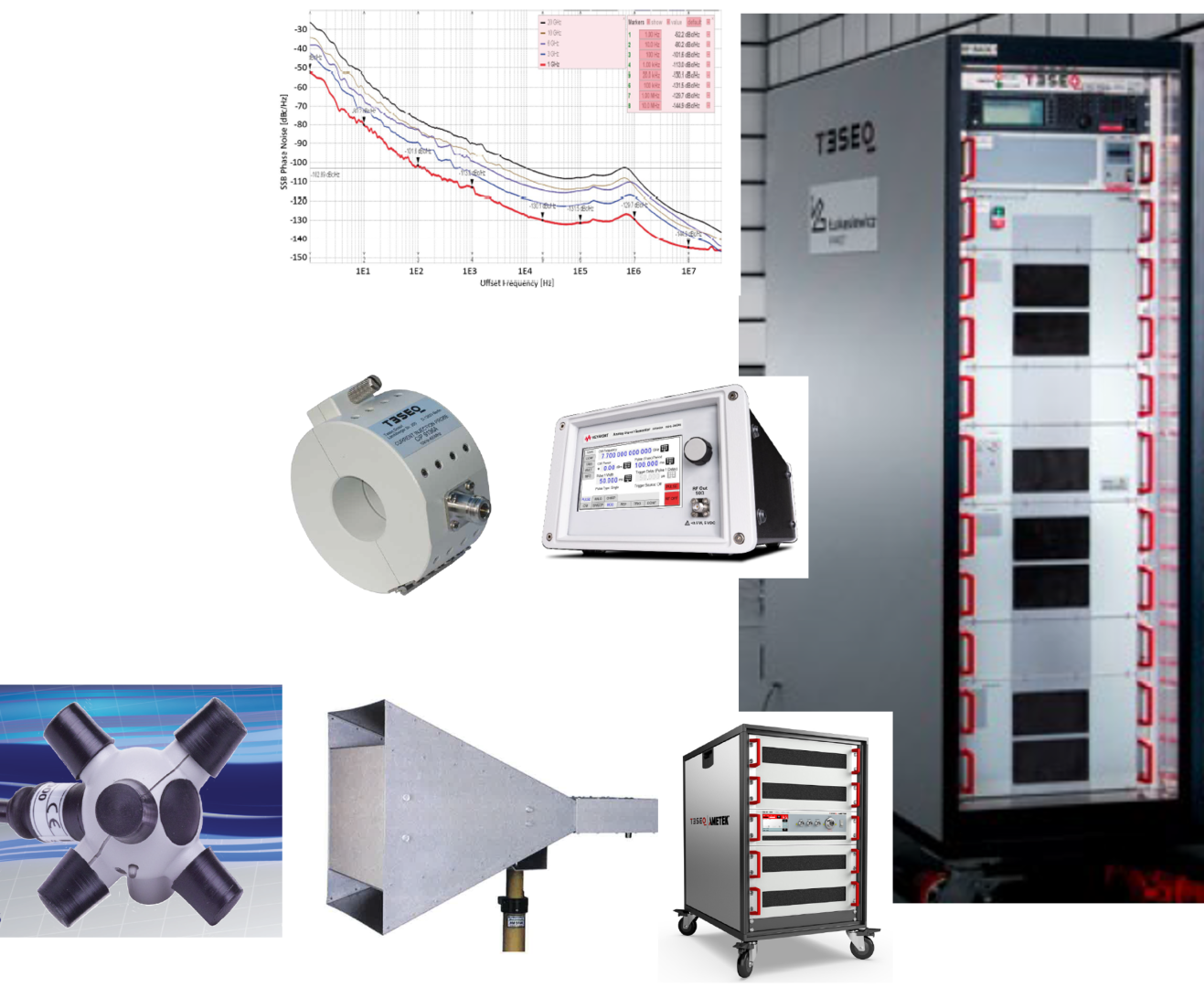

EMC testing – System for Testing Immunity to RF (Radio-Frequency) Disturbances

- The RF Immunity Test System enables evaluation of the resistance of electrical and electronic vehicle components to narrowband radiated electromagnetic energy.

- Testing is carried out in compliance with a wide range of international and manufacturer-specific standards, including ISO 11452-2, ISO 11452-4, UN Regulation No. 10 Rev.06 (20 MHz – 2 GHz; draft Rev.07 – 6 GHz), PSA B21 7110D, VW TL 81000, BMW GS 95002-2, FCA CS-00054, Ford FMC 1278, and MBN 50284-2.

- The system allows testing within the 100 kHz – 7.12 GHz frequency range, with field strengths up to 600 V/m, including radar pulse and Bulk Current Injection (BCI) methods.

- It ensures accurate simulation of electromagnetic fields encountered in vehicle environments, enabling comprehensive validation of EMC immunity for control modules, inverters, and high-voltage components.

HV EMC Test System for High-Voltage Component Testing (Battery Packs, E-Drives, Inverters)

- The High-Voltage EMC Test System enables electromagnetic compatibility testing of components used in electric powertrains, including battery packs, inverters, and e-drives, in accordance with ISO 21498-2 Ed.2 (sections 6.2–6.12) and VW80300 (parts EHV-01, 02, 03, 04, 05, 06, 08, 09, 10, 11, 13, 16).

- The setup incorporates a universal programmable AC/DC power supply system rated at 1500 VDC / 250 kVA, allowing simulation of realistic high-voltage network conditions.

- It includes a noise generator module reproducing fast switching transients typical of HV DC lines in electric vehicles, a ripple generator for high-voltage circuits, and a set of artificial networks for conducted emission and immunity testing.

- The operating frequency range extends from DC up to 500 kHz, covering the spectral domain relevant for EMC evaluation of modern electric and hybrid propulsion systems.

Expansion of the Competence Centre – development of modern drive systems

The BOSMAL Institute has received funding for the project entitled ‘Expansion of the Competence Centre – development of modern drive systems’. As part of the project, the following will be purchased:

- A specialised-dynamic hydraulic actuator with accessories for delay sensors and a multi-channel controller

- RF immunity test system

- ALSE chamber according to CISPR 25 requirements

- Battery test system according to VW 80300

- Analyser (set of analysers) for the measurement of at least HCHO, N2O, NO, NO2 and NH3 in the engine exhaust gas

- Particle counter PN10/PN23

- Mobile system for measuring exhaust emissions

The target group will primarily be vehicle manufacturers, suppliers of automotive parts and components, as well as research institutes and research centres for innovation in the automotive sector. The BOSMAL Institute also targets companies involved in electromobility, autonomous vehicle systems, as well as manufacturers of materials and eco-technologies used in transport, etc. These services will be dedicated to customers looking for advanced tools for testing, prototyping and implementation of state-of-the-art technological solutions, supporting them in increasing the efficiency, safety and sustainability of automotive products.

The main objective of the project is to expand the existing research infrastructure at the BOSMAL Institute.

Project value: PLN 22,755,000

Co-financing: 9 250 000 PLN

Back

to top